Introduction.

Ontario’s subsurface geology presents a complex mosaic of soft rock formations—shales, siltstones, and weathered bedrock—that pose unique challenges to tunneling projects. As urban infrastructure expands, particularly with projects like the Ontario Line and regional sanitary trunk sewers, the need for robust geotechnical characterization becomes paramount. Advanced testing methods such as geophysics, pressuremeter testing, overcoring, and detailed rock analysis are not merely technical options—they are strategic imperatives.

Geophysics: Mapping the invisible.

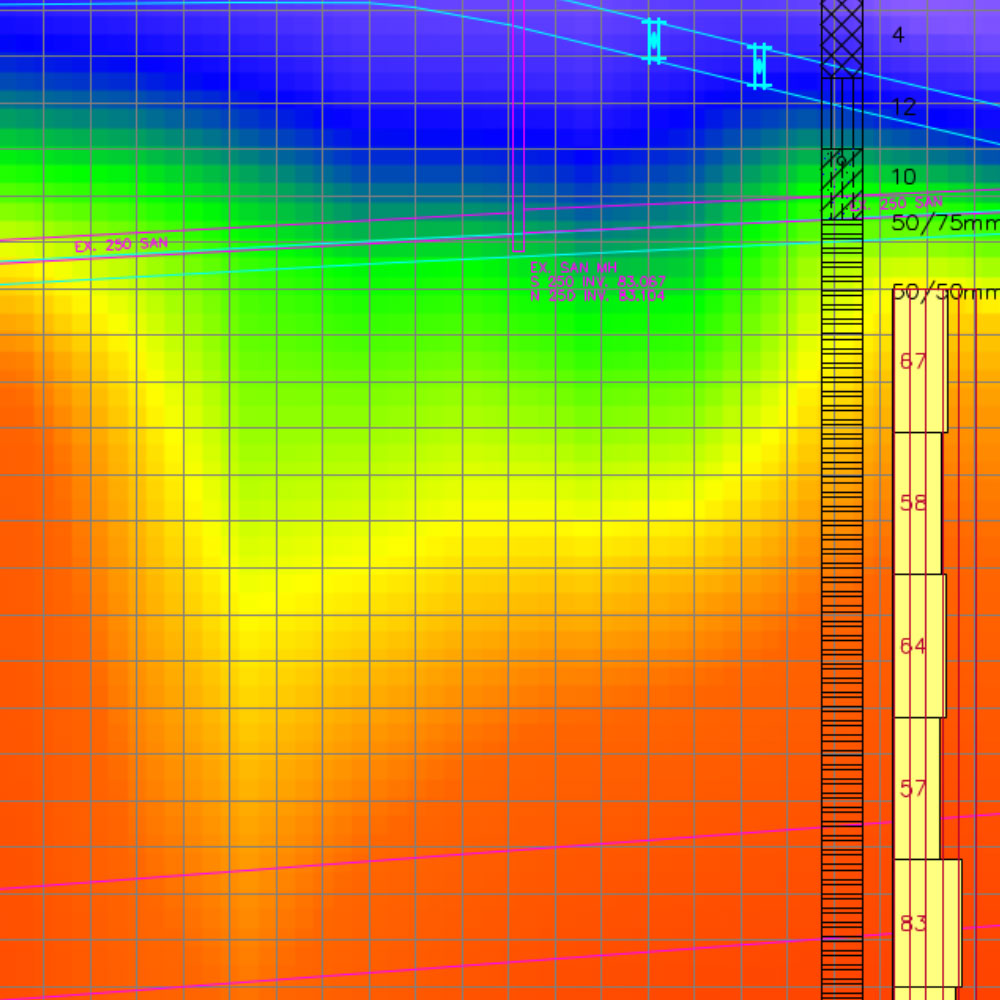

Geophysical methods, including seismic cone penetration tests and acoustic televiewers, offer non-invasive insights into subsurface conditions. These tools help delineate stratigraphy, detect anomalies, and assess rock mass quality before drilling begins. For instance, the Ontario Line project utilized seismic CPT and televiewer data to refine tunnel alignment and anticipate ground behavior.

Geophysics also supports risk mitigation by identifying zones of weakness, gas pockets, and groundwater pathways—critical for tunnel boring machine (TBM) performance and safety planning.

Pressuremeter testing: Quantifying deformability.

Pressuremeter testing (PMT) provides direct measurements of in-situ stress-strain behavior in soils and soft rock. In Ontario’s soft rock environments, PMT is invaluable for:

- Estimating modulus and yield pressure

- Designing support systems for shafts and tunnels

- Validating numerical models of ground deformation

Overcoring: Measuring in-situ stress.

Overcoring remains the gold standard for measuring in-situ stress in rock masses. It is especially critical in soft rock where stress relief features and weathering can distort conventional assumptions. Ontario projects have used USBM and CSIRO overcoring methods to:

- Determine horizontal stress fields at tunnel horizon depth

- Guide tunnel orientation and support design

- Assess rock mass behavior under excavation-induced stress changes

The precision of overcoring data directly influences the safety and cost-effectiveness of tunneling operations.

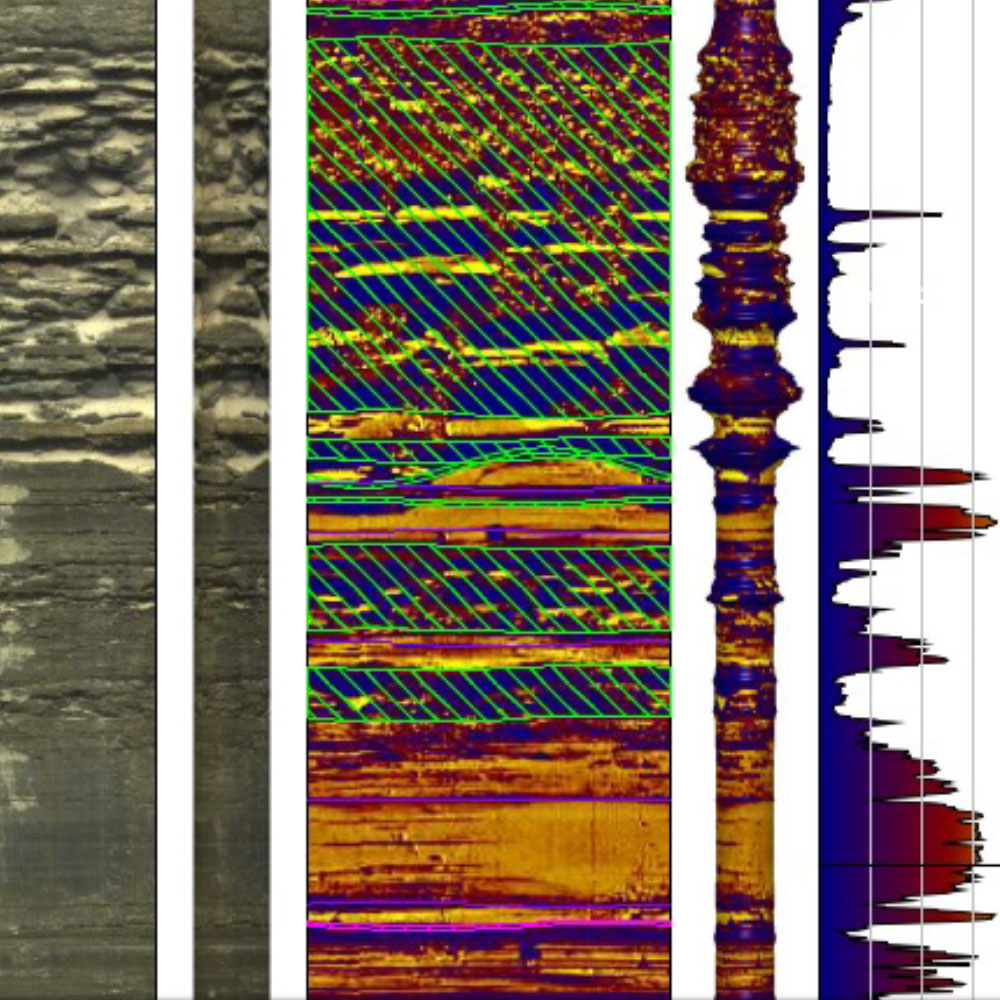

Rock analysis: Understanding material behaviour.

Advanced rock testing—such as uniaxial compressive strength (UCS), Brazilian tensile strength, slake durability, Cerchar abrasivity, and point load index—provides a comprehensive profile of rock performance. These tests inform:

- TBM cutterhead selection and wear prediction

- Ground support system design

- Settlement and deformation modeling

For example, the Indian Road Sanitary Trunk Sewer project conducted over 100 UCS and abrasivity tests to evaluate tunneling feasibility and optimize construction methods.

Integrated testing: A holistic approach.

The synergy of geophysics, PMT, overcoring, and rock analysis enables a multi-dimensional understanding of soft rock behavior. This integrated approach supports:

- Accurate ground characterization

- Predictive modeling of tunnel performance

- Adaptive construction strategies

As highlighted in the Tunnelling Association of Canada’s technical papers, inadequate site investigation correlates strongly with cost overruns and schedule delays. A borehole-to-tunnel ratio below 0.5 can lead to cost escalation.

Conclusion.

In Ontario’s evolving urban landscape, tunneling through soft rock demands more than conventional geotechnical investigation. It requires a strategic deployment of advanced testing methods to reduce uncertainty, enhance safety, and ensure project success. As demonstrated across multiple regional projects, these tools are not just diagnostic—they are transformative.